Beyond Carbon Dioxide (CO2), the combustion of fossil fuels may yield other pollutants such as Carbon Monoxide (CO), Nitrogen Dioxide (NO2), Sulfur Dioxide (SO2) and Particulate Matters (PM) that potentially give long-term impact to both the environment and health.

TNB is actively developing strategies to control and mitigate these pollutants across all our facilities, safeguarding the environment and health.

Pioneering Air Quality Improvement

Our unwavering dedication to enhancing air quality in our operational areas is evident through our relentless focus on reducing primary pollutants. We vigilantly monitor and curtail emissions of Sulfur dioxide (SO2), Nitrogen Dioxide (NO2), Carbon Monoxide (CO), and Particulate Matter (PM). This meticulous attention underscores our commitment to fostering a cleaner, healthier environment for all.

Adapting to Changing Regulations: Recognizing the rapidly evolving regulatory landscape for air emissions, all TNB power plants adhere to the rigorous Environmental Quality (Clean Air) Regulation (CAR) 2014.

This table outlines the specified emission limit for monitoring and reporting:

| Power Plant | CO, mg/m3 | NO2, mg/m3 | SO2, mg/m3 | Particulate Matter, mg/m3 |

|---|---|---|---|---|

| Gelugor Power Plant | 100 | *300 | ||

| TNB Prai Sdn Bhd | 100 | 150 | ||

| Connaught Bridge Sdn Bhd | 100 | 150 | ||

| Putrajaya Power Station | 100 | 150 | ||

| Southern Power Generation | 100 | 150 | ||

| Tuanku Jaafar Power Station | 100 | 150 | ||

| Kapar Energy Ventures | 100 | *600 | *3600 | *200 |

| Jimah East Power | 200 | 500 | 500 | 50 |

| TNB Janamanjung GF1 | 200 | *650 | *750 | *70 |

| TNB Janamanjung GF2 | 200 | 500 | 500 | 50 |

*Based on the given LTC limit by the DOE

Emission Control Measures

To achieve air emission compliance, TNB employs a range of advanced technologies and practices by optimising fuel mix and maintaining the effectiveness of emissions control facilities, such as:

Flue Gas Desulphurisation (FGD)

Implemented at TNB Janamanjung and JEP, reducing SO2 emissions significantly.

Electrostatic Precipitator (ESP)

Utilized at TNB Janamanjung and JEP for the removal of harmful particulate matter.

Low NOx Burners

Employed in gas plants to curtail NO2 emissions.

Transparent Monitoring and Swift Action

We maintain a vigilant eye on our emissions' performance, swiftly acting upon any irregularities. Adhering to stringent reporting protocols, any deviation in emissions is reported to the state Department of Environment (DOE) within 24 hours, with immediate rectification measures. Our commitment extends further with annual emission declarations submitted to the DOE

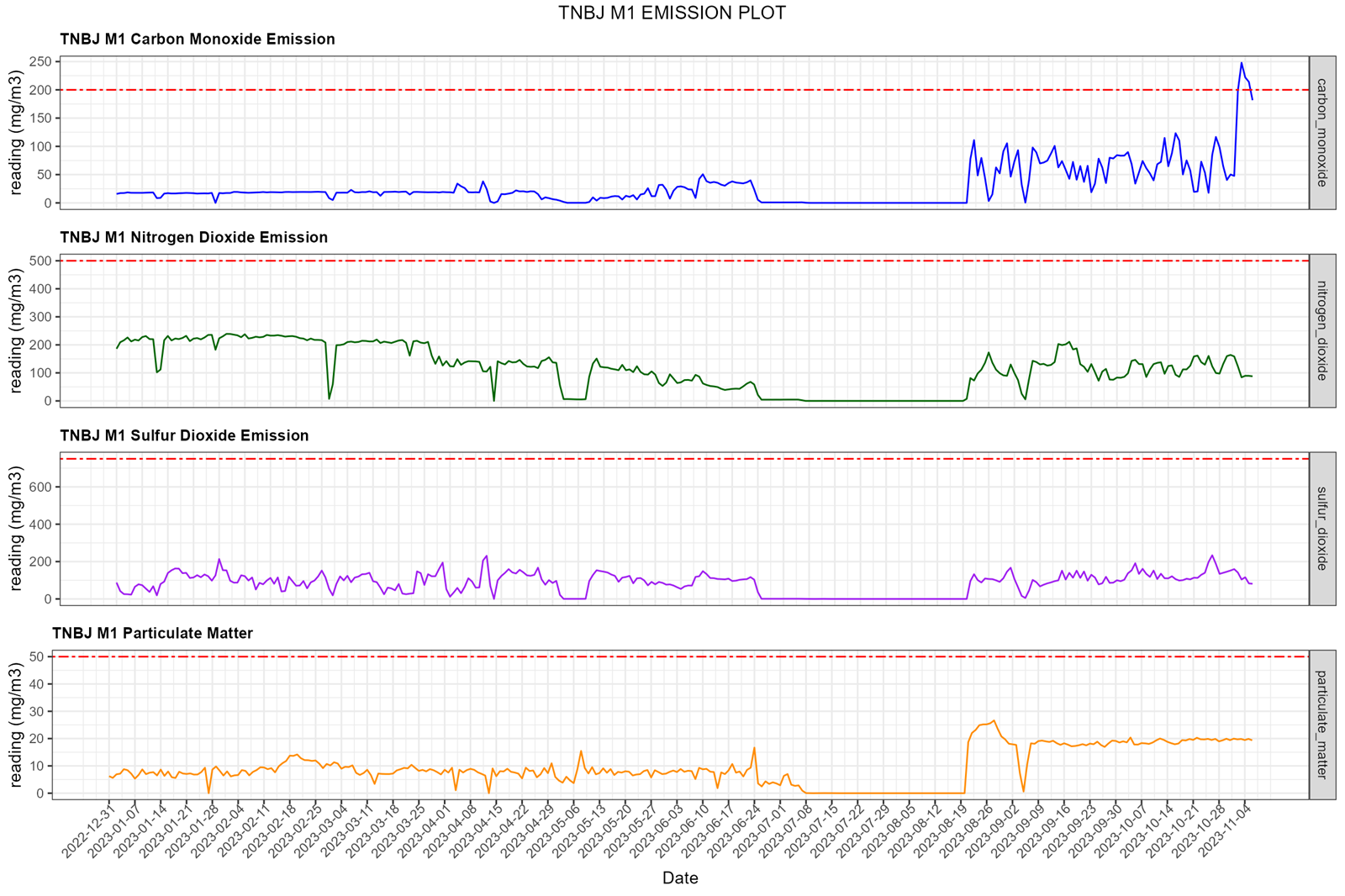

Below is a snapshot of the emission levels recorded by the 700MW TNB Janamanjung Unit 1, compared against the DOE limits, during the period from January 1st, 2023, to November 5th, 2023:

Ongoing Initiatives for Emission Reduction

Continual efforts drive us to explore innovative solutions:

EFB-Pellet Trial Burn

Conducted at Jimah East Power (JEP) U20, yielding remarkable emission reductions, marking a significant milestone in Malaysia's biomass-fired supercritical boilers.

Biomass Integration Program

Implemented at Kapar Energy Ventures (KEV) in collaboration with IHI Power System Malaysia. The initiative aims to phase in biomass use, showcasing encouraging results and a commitment to reduce emissions further.

Coal Blending Initiatives

Ongoing at JEP and under consideration at KEV, focusing on utilizing coal with lower ash content to reduce emissions.

A Pledge to a Greener Future

At TNB, our dedication to combating climate change and enhancing air quality resonates through tangible actions and ongoing initiatives. We remain steadfast in our commitment to nurturing a sustainable, healthier planet for generations to come.