This article was first published on 30 September 2024, and updated on 30 March 2025.

Hazardous waste is designated as scheduled waste, encompassing solid, semi-solid, liquid, or gaseous substances that pose significant risks to human health and the environment if not managed properly. According to the Malaysia Environmental Quality (Scheduled Wastes) Regulations 2005, scheduled waste includes waste listed in the First Schedule of the Regulation, which consists of 77 types of scheduled waste categorised into five groups:

- SW 1: Metal and metal-bearing wastes.

- SW 2: Wastes containing principally inorganic constituents, which may contain metals and organic materials.

- SW 3: Wastes containing principally organic constituents, which may contain metals and inorganic materials.

- SW 4: Wastes which may contain either inorganic or organic constituents.

- SW 5: Other wastes.

We are committed to adhere to ethical disposal practices for scheduled waste in our ongoing efforts to minimise environmental impact and support sustainable development goals.

Hazardous Waste Management Process and Method

At TNB, our primary principle is the prevention of waste generation, including hazardous waste. When hazardous waste is unavoidable in our operations, we manage it responsibly through the 4R approach—Reduce, Reuse, Recycle, and Recover. Together with our robust circular economy practices and proactive waste prevention initiatives, we are committed to minimizing environmental impact and promoting sustainable waste management.

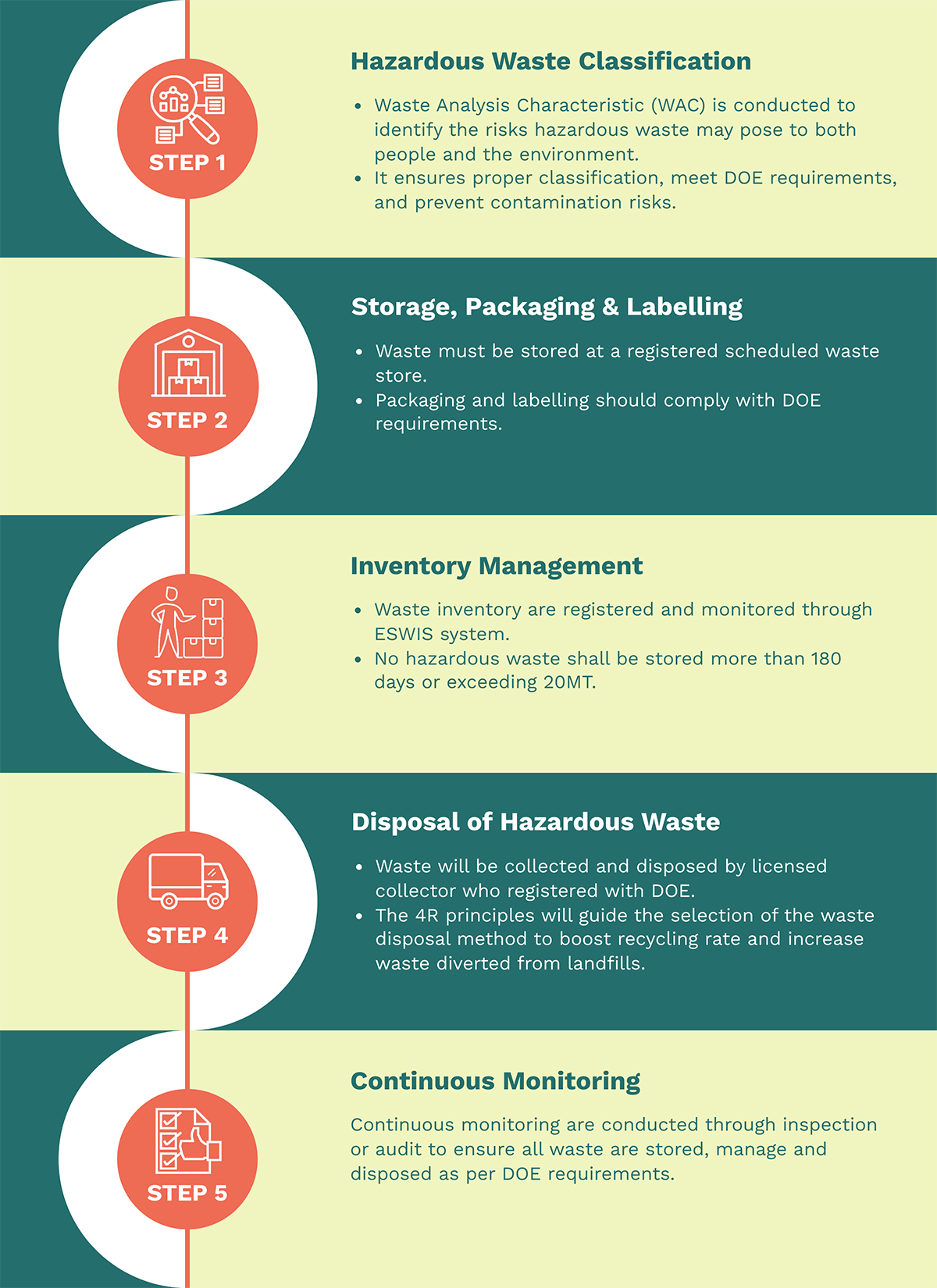

We are dedicated to implementing responsible and diligent hazardous waste management across all levels of our operations. Our hazardous waste management practices fully comply with the Environmental Quality (Scheduled Wastes) Regulations 2005, under the Environmental Quality Act 1974, as enforced by the Department of Environment (DOE) Malaysia. The hazardous waste follows a standardized management process, as outlined below.

TNB Hazardous Waste Management Process

We collaborate with licence waste collectors to select the most appropriate and sustainable treatment method according to 4Rs approach with the aim to minimize environmental impact and promote sustainable waste management.

The table below provides a summary of the waste generated from TNB operations and the corresponding treatment methods, based on our initial engagement with the licensed waste collectors. These treatment methods shall be validated with data collected by the licensed waste collectors.

| No | SW Code | SW Description | Method of Treatment |

|---|---|---|---|

| 1 | SW 104 | Dust, slag, dross or ash containing arsenic, mercury, lead, cadmium, chromium, nickel, copper, vanadium, beryllium, antimony, tellurium, thallium or selenium excluding slag from iron and steel factory (Fly ash) | REUSE |

| 2 | SW 110 | Waste from electrical and electronic assemblies containing components such as accumulators, mercury-switches, glass from cathode-ray tubes and other activated glass polychlorinated biphenyl-capacitors, or contaminated with cadmium, mercury, lead, nickel, chromium, copper, lithium, silver, manganese or polychlorinated biphenyl |

60% RECYCLE/RECOVERY 30% NORMAL WASTE 10% E-WASTE |

| 3 | SW 305 | Spent lubricating oil | RECYCLE |

| 4 | SW 306 | Spent hydralic oil | RECYCLE |

| 5 | SW 421 | Used Paper Insulated Lead Cable | RECOVERY |

| 6 | SW 422 | A mixture of scheduled and non-scheduled wastes (Transformer) | RECOVERY & RECYCLE |

| 7 | SW 102 | Waste of lead acid batteries in whole or crushed form | CEMENTATION / RECYCLE |

| 8 | SW 103 | Waste of batteries containing cadmium and nickel or mercury or lithium | CEMENTATION / RECYCLE |

| 9 | SW 109 | Waste containing mercury or its compound | PHYSICAL/CHEMICAL TREATMENT |

| 10 | SW 307 | Spent mineral oil-water emulsion | INCINERATION (AQ) |

| 11 | SW 311 | Waste oil or oily sludge | INCINERATION (BK) |

| 12 | SW 408 | Contaminated soil, debris or matter resulting from cleaning-up of a spill of chemical, mineral oil or scheduled wastes | LANDFILL |

| 13 | SW 409 | Disposed containers, bags or equipment contaminated with chemicals, pesticides, mineral oil or scheduled wastes | INCINERATION (ML) |

| 14 | SW 410 | Rags, plastics, papers or filters contaminated with scheduled wastes | INCINERATION (BK) |

| 15 | SW 417 | Waste of inks, paints, pigments, lacquer, dye or varnish | INCINERATION (ML) |

| 16 | SW 429 | Chemicals that are discarded or off-specification (used Polybutene / grease) | INCINERATION (BK) |

Continuous Monitoring Through Pro-active Gap Identification

Our commitment to excellence extends beyond compliance; we proactively enhance our waste management processes through rigorous site inspections, external audits, and internal audits.

In 2023, TNB has registered 7 relevant operation entities within our divisions/departments/subsidiaries in obtaining ISO14001 full certification which required recertification by external independent auditors at least once every three years.

Internally, TNB has instituted annually Health, Safety and Environment (HSE) Corporate Audit which includes hazardous waste management to ensure the safe, responsible, and continuous adherence to hazardous waste regulations. Under the TNB HSE Corporate Audit, internal audit will be conducted by HSE Corporate at relevant operation sites to assess compliance with scheduled waste management requirement.

The Role of TNB's HSE Corporate in Hazardous Waste Management

TNB's Health, Safety, and Environment (HSE) team is critical in reviewing and approving proposed corrective actions for identified non-conformances. Their responsibilities encompass several focal points:

Evaluating Effectiveness

The HSE team ensures that proposed actions adequately address non-compliance and prevent future occurrences. They assess the feasibility and effectiveness of proposed solutions to ensure they effectively resolve the identified issues.

Compliance Verification

They confirm that actions align with relevant regulations and best practices, safeguarding continued compliance. The HSE team ensures that corrective actions adhere to established environmental regulations and industry best practices.

Future Goals and Sustainability of the Hazardous Waste Management

As part of TNB's broader efforts, the TNB HSE Corporate Audit actively contributes to minimising waste generation, maximising recycling opportunities, and adhering to the highest environmental standards. This is achieved through:

Compliance and Risk Management

The programme minimises environmental risks associated with waste management by ensuring adherence to regulations. Proper waste handling and disposal practices safeguard the environment and public health, reducing the likelihood of environmental contamination, accidents, and health issues.

Promoting Best Practices

The programme encourages continuous improvement and adoption of sustainable waste management practices throughout our operations. This includes initiatives like waste minimisation, segregation at source, recycling, and responsible disposal. Promoting best practices enhances our environmental performance and sets a positive example for other organisations.

Improved Waste Management

The programme leads to more efficient waste segregation, handling, and disposal, reducing the environmental impact of TNB's activities. Effective waste management practices minimise the amount of waste generated, ensure proper treatment and disposal, and contribute to a more sustainable waste management system.

Environmental Awareness

The programme raises employee awareness about responsible waste management practices, fostering a culture of environmental responsibility within TNB. Through training programs and communication initiatives, employees gain a deeper understanding of the importance of proper waste handling and their role in contributing to a sustainable future.

As of August 2024, the TNB HSE Corporate Audit has demonstrated a thorough verification process in managing hazardous waste. Key accomplishments include:

| Programme Achievement | Description |

|---|---|

| Hazardous waste facility improvement | TNB's hazardous waste storage facilities are continuously being improved and upgraded based on audit findings to ensure full compliance with DOE requirements. |

| Enhance compliance on competency requirements | In 2023, TNB had 78 employees registered as Certified Environmental Professionals in Scheduled Waste Management (CEPSWaM). As of August 2024, this number increased to 106, highlighting the company's commitment to environmental sustainability and regulatory compliance on hazardous waste management. |

| Enhanced Environmental Protection Through Audit and Inspection | Minimised environmental risks associated with improper waste handling, leading to a safer environment for employees and surrounding communities. |

| Sustainable Waste Management Culture | Fostered a culture of continuous improvement and responsible waste management within TNB, enhancing the company's reputation as a leader in environmental stewardship. |

In addressing non-compliance, we utilise a strategic approach to address non-conformances identified during inspections. This approach ensures timely reporting, investigation, and resolution of non-compliance issues through:

Structured Non-Conformance Report (NCR) Management

A clear process ensures all non-conformances are reported promptly through eHSE-NCR system (an online HSE digital online platform designed specifically for raising, tracking, and monitoring NCRs). Dedicated personnel are responsible for logging and tracking each reported issue.

Root Cause Identification

Investigations thoroughly explore the root causes of non-conformances, enabling targeted corrective and preventive actions to prevent recurrence. Each nonconformance will be assigned to a dedicated person in charge, who is responsible for implementing the necessary corrective and preventive measures. All actions must be completed within the committed timeframe and will be monitored through the eHSE-NCR system.

All identified areas for improvement are promptly raised as Nonconformance Reports (NCR) and systematically logged in the eHSE-NCR system, an online platform designed specifically for raising, tracking, and monitoring NCRs. Each NCR will be assigned to a dedicated person-in-charge (PIC), responsible for implementing the necessary corrective and preventive actions. Once the root cause is identified, both corrective and preventive measures will be executed within the committed timeframe. This comprehensive system enhances accountability, enables timely resolutions, and promotes continuous improvement in our waste management practices.

Complementing TNB's Hazardous Waste Management

Since 2022, the Self Visual Report (SVR) has been implemented across all divisions, departments, and subsidiaries. SVR is a self-reporting visual report that consists of 24 elements, such as hazardous waste inventory records, competency records, labeling conditions, and overall pictorial assessments of store and waste conditions.

Each scheduled waste store submits this report on a monthly basis, covering key elements to ensure compliance with the Department of Environment’s requirements. The report is prepared and submitted by a Certified Environmental Professional in Scheduled Waste Management (CEPSWaM) to the HSE Corporate team, and its submission is mandatory.

| Inspection or audit conducted for Hazardous Waste | 2022 | 2023 | 2024 (as of August 2024) |

|---|---|---|---|

| Inspection by HSE Corporate on hazardous waste at relevant operation site | 8 | 15 | 6 |

| Self-Visual Reporting (SVR) by division/department | 736 | 948 | 640 |

| Audit inclusive of Schedule Waste Management at relevant operation site | 5 | 7 | 1 |

We have successfully reduced the amount of hazardous waste generated by 3.67% in 2024 (895,038 MT) compared to the previous year (929,123 MT). Of this hazardous waste, 55.58% (497,452 MT) was recycled.

Responsible Effluent Management

In mitigating legal and operational risks and ensuring that effluents meet quality standards to protect public health and the environment, we have developed the Industrial Effluent Treatment System (IETS) Management Guideline.

Industrial effluent treatment systems are fundamental in managing wastewater generated by TNB to safeguard the environment and ensure compliance with regulatory requirements. These systems encompass various stages and processes designed to remove contaminants from the effluent before its safe discharge into the environment.

By strengthening this programme, TNB remains committed to responsible waste management, environmental protection, and achieving our long-term sustainability goals. The programme plays a key role in ensuring our operations are conducted in an environmentally responsible manner.

Revision History:

30 March 2025: Added data on hazardous waste generated and recycled in 2024, and added details on Effluent Management.