At TNB hazardous waste is managed in accordance with Environmental Quality Regulations (Scheduled Waste) 2005 requirements under the Environmental Quality Act 1974 by the Department of Environment (DOE) Malaysia

Abbreviations:

Abbreviations:

- SW: Scheduled Waste

- CePSWaM: Certified Environmental Professional in Scheduled Waste Management

- PCB: Polychlorinated Biphenyl

- E-Waste: electrical and electronic waste

- NCL: Notice, Compound, Lawsuit

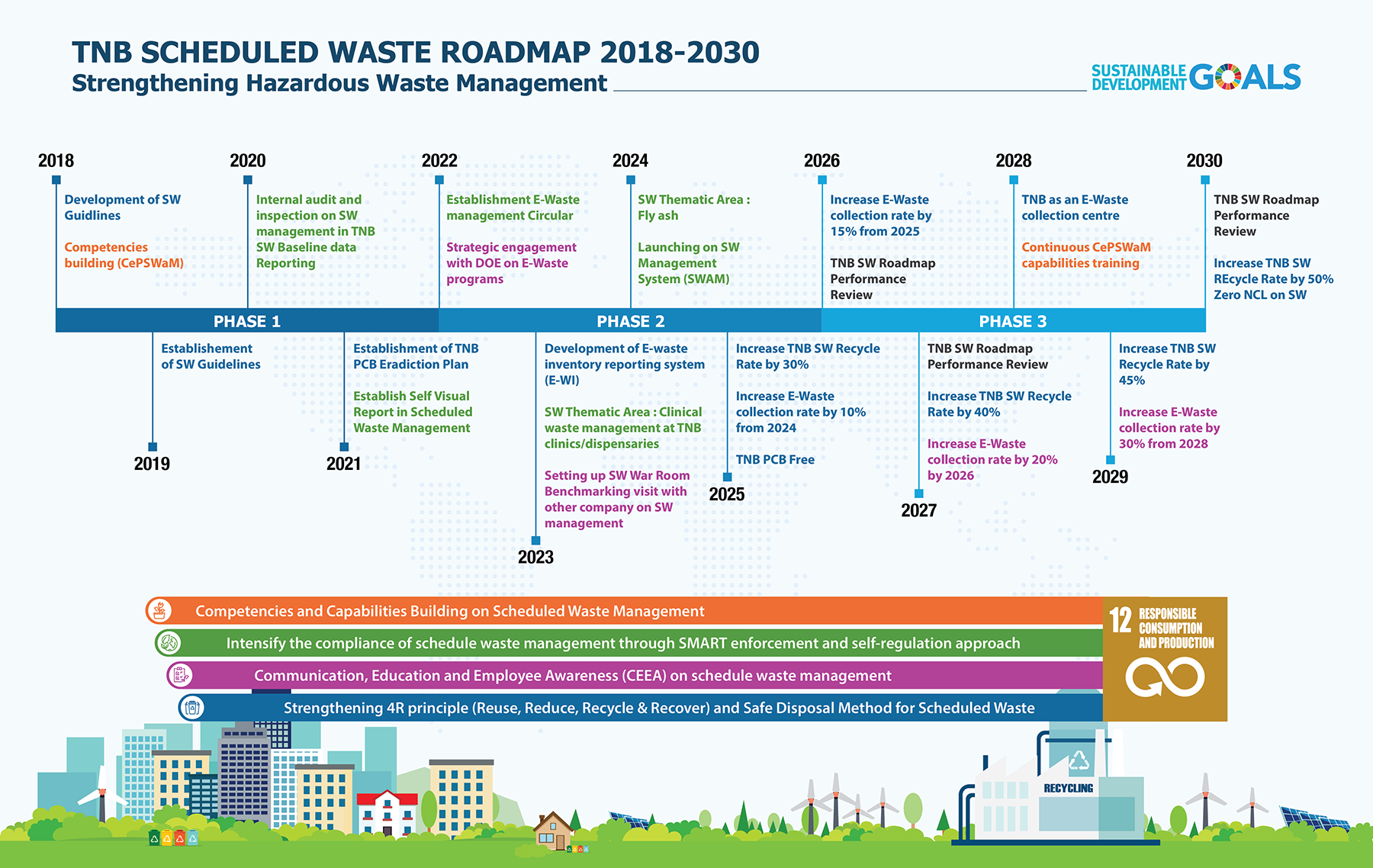

In alignment with the United Nation’s Sustainability Development Goal 12 (SDG12) – Responsible Consumption and Production - TNB Scheduled Waste Roadmap 2018 – 2030 was developed to strengthen hazardous waste management in TNB. The vision of this Roadmap is to take a phased approach by involving all employees and key stakeholders in jointly addressing scheduled waste management to maximize resource value, while minimizing – and even eliminating – environmental impact.

Guided by 5 principles – sustainable development, shared responsibility, precautionary, participatory, and good governance - 4 implementation strategies were identified:

Building competencies and capabilities of employees handling scheduled waste

Ensuring compliance through SMART enforcement and self-regulation

Increasing employee awareness through communication and education

Strengthening the 4R principle (Reuse, Reduce, Recycle, Recover) and Safe Disposal Method for Scheduled Waste

Efforts are in place to establish baseline data for hazardous waste recycling rate. TNB strives to strengthen our commitment to reducing the total waste directed to disposal by setting 30% recycling rate of Hazardous Waste by 2025. Targets will be reviewed regularly based on the progress of these efforts, in line with national targets (reference: Department of Environmental Strategic Engagement Plan 2021 – 2030 for hazardous waste management). This is important to substantially reduce waste generation through prevention, reduction, recycling, and reuse by 2030, in accordance with target 12.5 of SDG12.

Building awareness, competencies, and capabilities

The role of TNB’s Certified Environmental Professional in Scheduled Waste Management (CePSWaM) is critical to ensure adherence to all regulatory requirements on scheduled waste management. They:

- Provide advisory to TNB Divisions/Departments/Subsidiaries and employees on complying to Environmental Quality Regulations (Scheduled Waste) 2005 requirements and related environmental laws under the Environmental Quality Act 1974.

- Identify and classify scheduled waste categories

- Regulate movements of the identified scheduled wastes

- Provide guidance on the provision of storage and packaging facilities, and ensure that scheduled waste labeling meets legal requirements

- Ensure that the appointed contractor meets the licensing requirements for the designated scheduled waste premises and facilities as well as a valid transport license from the DOE

Currently there are 88 Certified Environmental Professionals in Scheduled Waste Management in the TNB Group.

Collaboration with TNB Integrated Learning Solution (ILSAS)

Aside from the certified professionals, it is also important to ensure that employees in TNB Group understand the importance of proper waste handling and are equipped with the knowledge to manage scheduled waste responsibly.

To this end, we collaborate with TNB Integrated Learning Solution (ILSAS) to develop training module for Scheduled Waste Handlers. This module is reviewed periodically to ensure the content is up to date with the most recent regulatory requirements and company’s sustainability direction.

Pro-active gap identification

Our commitment to excellence extends beyond compliance; we proactively enhance our waste management processes through rigorous site inspections and internal audits. Moreover, the implementation of Self Visual Reporting (SVR) across every division, department, and subsidiary within TNB serves as a dynamic tool for analysis and identification of gaps, driving our relentless pursuit of continuous improvement.

In October 2023 we introduced the E-Waste Inventory System (E-WI) and TNB Solid Waste Inventory System (TESWI) – tools developed for electrical and electronic waste and solid waste data collection respectively. These tools will help us track both hazardous and non-hazardous waste, ensuring thorough monitoring and diversion from disposal.

In line with our environmental policy, we will leverage the data gathered from the E-WI and TESWI to establish a baseline for our waste directed and diverted from disposal. This analysis serves as a foundational step in understanding our current usage patterns, enabling us to craft an informed waste reduction strategy.

| Activity | 2022 | 2023 (Oct23) |

|---|---|---|

| Inspection by HSE Department | 8 | 14 |

| Self-Visual Reporting (SVR) by division/department | 736 | 790 |

| Audit inclusive of Schedule Waste Management | 5 | 4 |

Following these audits, a comprehensive assessment resulted in the issuance of nine (9) Non-Conformance Reports (NCR) to the concerned divisions, departments, and subsidiaries. Swift corrective measures were promptly implemented, leading to the successful closure of all NCRs. Our commitment to rectification underscores our dedication to maintaining the highest standards of operational excellence.

Strengthening the 4R principle

We are dedicated to safeguarding the environmental ecosystem through the implementation of an efficient circular economy and a proactive approach to waste and pollution prevention. Our management of hazardous waste strictly adheres to the Environmental Quality (Scheduled Wastes) Regulations of 2005 under the Environmental Quality Act of 1974.

Our commitment to reducing hazardous waste is centered on enhancing the recycling rate of such waste. In collaboration with our licensed waste collectors, approved by local regulators, we are actively engaged in analyzing waste treatment methods documented in the waste consignment notes. The initial step in quantifying the hazardous waste recycling rate involves the verification of the treatment methods. This process is necessary in identifying our baseline and but also sets targets for improvement in our ongoing efforts towards responsible hazardous waste management.

Table 1: Scheduled Waste Generated (2019 – 2022) as reported in TNB Sustainability Report 2022

| Year | Total Scheduled Waste Generated (metric tonnes) |

|---|---|

| 2019 | 34,783 |

| 2020 | 23,576 |

| 2021 | 47,829 |

| 2022 | 74,150 |

Top 5 waste generated in 2022

1. SW104 – Fly Ash

2. SW110 – E-waste such as lanterns, electronic meters

3. SW422 – Used transformers

4. SW305 – used oil transformer

5. SW410 – contaminated spill kit, rug, cotton

The treatment and recycling of scheduled waste involve various methods to minimize environmental impact and promote sustainable waste management. The specific methods used can depend on the type and characteristics of the scheduled waste.

We are evaluating the treatment methods for specific scheduled waste through engagement and verification with licensed waste collectors. To illustrate our progress, the table below summarizes the waste generated from TNB operations and its treatment methods based on our initial engagement with the licensed waste collectors. These treatment methods shall be validated with data collected by the licensed waste collectors.

| No. | SW Code | SW Description | Method of Treatment |

|---|---|---|---|

| 1. | SW 104 |

Dust, slag, dross or ash containing arsenic, mercury, lead, cadmium, chromium, nickel, copper, vanadium, beryllium, antimony, tellurium, thallium or selenium excluding slag from iron and steel factory (Fly ash) |

REUSE |

| 2. | SW 110 | Waste from electrical and electronic assemblies containing components such as accumulators, mercury-switches, glass from cathode-ray tubes and other activated glass polychlorinated biphenyl-capacitors, or contaminated with cadmium, mercury, lead, nickel, chromium, copper, lithium, silver, manganese or polychlorinated biphenyl |

60% RECYCLE/RECOVERY |

| 3. | SW 305 |

Spent lubricating oil |

RECYCLE |

| 4. | SW 306 |

Spent hydraulic oil |

RECYCLE |

| 5. | SW 421 |

Paper Insulated Lead Cable Terpakai |

RECOVERY |

| 6. | SW 422 |

A mixture of scheduled and non-scheduled wastes (Transformer) |

RECOVERY & RECYCLE |

| 7. | SW 102 |

Waste of lead acid batteries in whole or crushed form |

CEMENTATION / RECYCLE |

| 8. | SW 103 |

Waste of batteries containing cadmium and nickel or mercury or lithium |

CEMENTATION / RECYCLE |

| 9. | SW 109 |

Waste containing mercury or its compound |

PHYSICAL/CHEMICAL TREATMENT |

| 10. | SW 307 |

Spent mineral oil-water emulsion |

INCINERATION (AQ) |

| 11. | SW 311 |

Waste oil or oily sludge |

INCINERATION (BK) |

| 12. | SW 408 |

Contaminated soil, debris or matter resulting from cleaning-up of a spill of chemical, mineral oil or scheduled wastes |

LANDFILL |

| 13. | SW 409 |

Disposed containers, bags or equipment contaminated with chemicals, pesticides, mineral oil or scheduled wastes |

INCINERATION (ML) |

| 14. | SW 410 |

Rags, plastics, papers or filters contaminated with scheduled wastes |

INCINERATION (BK) |

| 15. | SW 417 |

Waste of inks, paints, pigments, lacquer, dye or varnish |

INCINERATION (ML) |

| 16. | SW 429 |

Chemicals that are discarded or off-specification (used Polybutene / grease) |

INCINERATION (BK) |

Verification visit on schedule waste treatment method at EPIC Cenviro (Kualiti Alam),Bukit Pelanduk, Seremban, Negeri Sembilan

In the subsequent phase, our primary focus centers on validating the treatment method and accurately quantifying the total hazardous waste. Through a collaborative effort, we closely collaborate with licensed waste collectors to establish a robust baseline for recycling rates. Our commitment extends to the proactive identification and implementation of strategies aimed at elevating recycling rates, aligning with our overarching target for environmental sustainability.